Metalworking fluids (MWFs) play a crucial role in enhancing the efficiency of metalworking processes, including machining, grinding, and cutting. These fluids, which can be categorised as neat oils, water-based emulsions, or synthetic fluids, serve as both lubricants and coolants. As essential components in various industrial applications, MWFs contribute to improved tool life, better surface finish, and increased overall productivity - however, present an often overlooked risk.

Types of Metalworking Fluids:

- Neat oils: These mineral oil-based fluids offer excellent lubrication and are often used for heavy-duty tasks.

- Soluble/water-based oils: These water-mixable concentrates form milky emulsions when diluted. They offer a balance of cooling and lubrication.

- Synthetic fluids: These high-tech formulations are free of petroleum oils and often designed for specific applications.

Any metalworking fluid, regardless of its base type, can become dangerous if contaminated with bacteria, fungi, or metal particles. These contaminants can trigger respiratory issues, skin infections, and other health problems.

Health Risks of Exposure to Metalworking Fluids

Skin Irritation:

- Direct contact with MWFs can lead to skin irritation. This is a common health risk among workers involved in metalworking processes.

- Proper measures must be taken to minimise skin exposure, as prolonged contact may result in dermatitis and other skin-related issues.

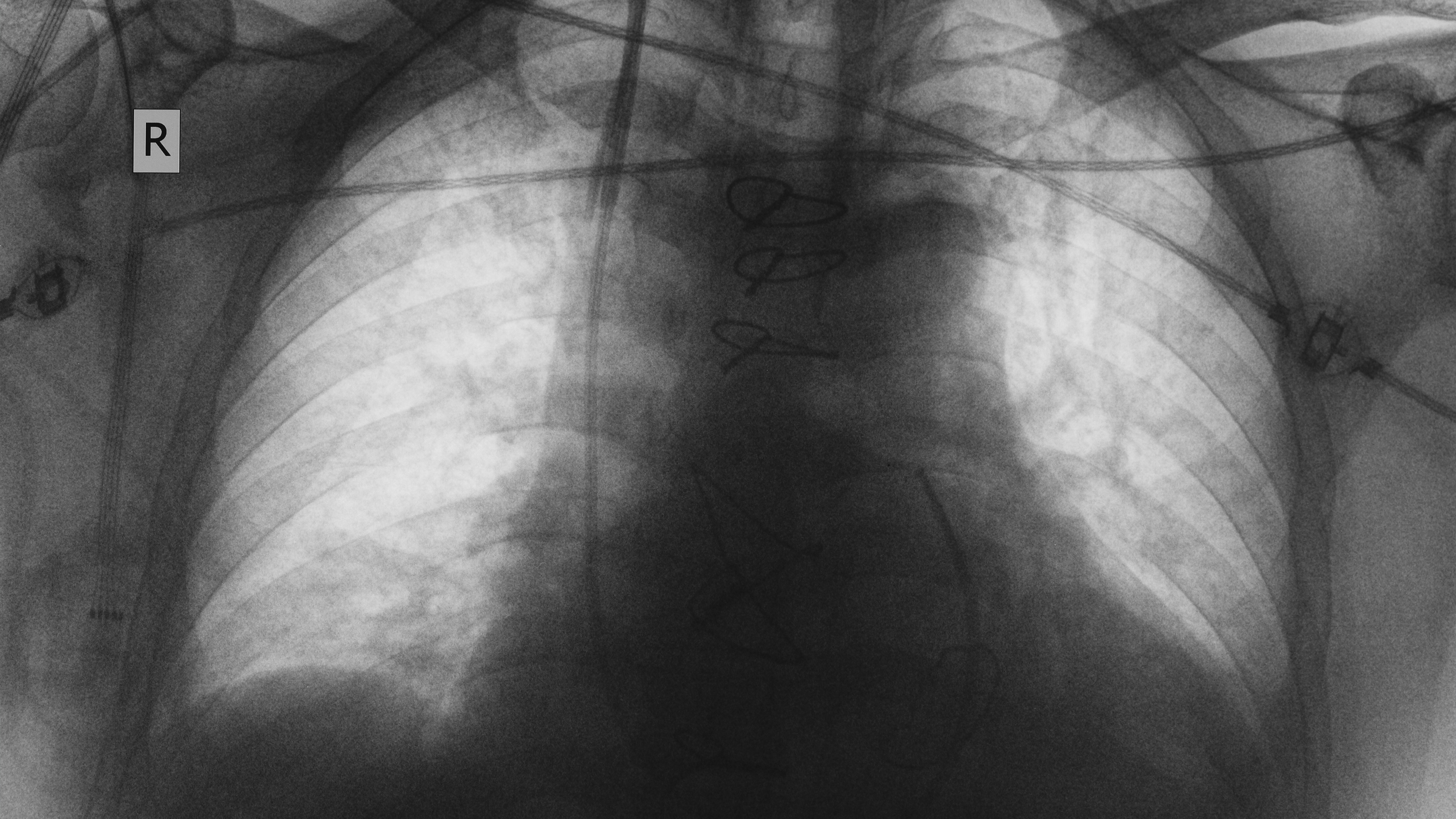

Lung Diseases:

- Inhaling mists or vapours generated during metalworking activities pose a significant risk to lung health, leading to several lung diseases, including occupational asthma, bronchitis, irritation of the upper respiratory tract, and occupational hypersensitivity pneumonitis.

- Respiratory problems and severe lung diseases can develop over time, making it imperative to implement measures to control airborne exposure.

Symptoms of Lung Disease:

- Difficulty breathing (dyspnea): Shortness of breath, air hunger, worsening with exertion or lying down.

- Persistent cough: Coughing for weeks or months, not improving with home remedies, dry/wet/hacking/wheezing.

- Chest pain: Pain or tightness in the chest, worsening with breathing or coughing.

- Wheezing: High-pitched whistling sound during breathing, indicating narrowed airways.

- Mucus production: Excessive mucus, especially discoloured (green, yellow, or bloody).

- Fatigue and tiredness: Feeling unusually tired or lacking energy, even after rest.

- Unintentional weight loss: Significant weight loss without trying, a worrying sign in some lung diseases.

- Fever: Not always present, but can accompany lung infections or inflammatory conditions.

- Clubbing of fingers: Fingertips and nail beds enlarging and curving in some chronic lung diseases.

Cancer:

- Before 1985 Long-term exposure to certain components in metalworking fluids had been linked to an increased risk of cancer. Today's refined neat oils, though safer, can still produce carcinogenic substances (polycyclic aromatic amines and nitrosamines) in specific conditions. Proper management of metalworking fluids minimises the likelihood of significant carcinogen presence.

Protecting Workers from Health Risks

Storage:

- Keep concentrates indoors (5-40°C) in labelled containers, raise and cover fluids stored outdoors, separate any incompatible materials, and watch for leaks. Weekly checks are considered good practice. Don't forget your MWF's specific storage instructions in the Safety Data Sheet, and consult a health and safety expert for full HSE compliance.

Ventilation Systems:

- Implementing effective ventilation systems is crucial to removing mists and vapours from the workplace air.

- Regular maintenance and monitoring of these systems are essential to ensure their efficiency in minimising airborne contaminants.

Air Quality Monitors:

- Fixed and handheld monitors detect air contaminants, triggering safety measures when needed. Real-time monitoring, whether at fixed locations or during spot checks, reduces worker exposure to MWF mist, safeguarding health. Check that monitors have appropriate sensors for your specific hazards.

Fluid Quality Maintenance:

- Ensuring the quality of metalworking fluids is paramount in preventing the growth of bacteria and fungi. According to the Health and Safety Executive (HSE), fluid systems that contain water or water mixes can become highly contaminated with harmful bacteria. The bacterial contamination of fluids and associated machinery and pipework should be closely monitored and controlled.

- Regular testing and maintenance of fluid quality help control microbial contamination, safeguarding workers from potential health hazards.

Personal Protective Equipment (PPE):

- Minimising skin contact through appropriate PPE, such as gloves and protective clothing, is fundamental.

- Employers should provide workers with high-quality PPE and enforce its consistent use to reduce the risk of skin-related issues.

Training Programs:

- Education and awareness are key components in protecting workers from the health risks associated with MWFs.

- Comprehensive training programs should be implemented to educate workers about potential hazards, safe handling practices, and the importance of using protective measures.

Regular Health Monitoring:

- Establishing regular health monitoring programs can help detect early signs of exposure-related health issues.

- Routine medical check-ups and screenings contribute to the early identification and management of potential health risks among workers.

While metalworking fluids are indispensable in industrial processes, the health risks associated with their use demand careful attention. By implementing robust control measures, employers can create a safer working environment, ensuring the well-being of their workforce and minimising the potential health impacts of metalworking fluids.

-1.png)